Aprilia Enjoy Controller Eng

APRILIA ENJOY > Inforazioni tecniche sui prodotti Aprilia Enjoy

The ATR-056 controller was conceived, patented, designed and has been manufactured by our company since 2014. Originally created for Aprilia products, it was in 2015 made to be used with both brush and brushless motors, making it usable on any type of motor. It integrates a multitude of innovative functions compared to standard ECUs. There is no need to manage it from smarthone, as it is preconfigured at the factory for general use that normally satisfies all users. Unless there are special requests from the end user, it is programmed on three power levels sed specifically 150W in continuous mode at the first level (ECO) for quiet progress, 250W (NORMAL) in continuous assistance mode at the second level), 750W (OFF ROAD with user responsibility) in pulse or continuous mode at the third level (HILL). However, the user can decide to connect the phone via Bluetooth to the controller and modify the performance by making up to 20 custom configurations, which can be uploaded to the switch at will instantly. Apart from the app that allows access and modification of every parameter of the control system, engine, battery, and performance the controller itself allows the user to take advantage of many proprietary capabilities and in particular:

- (option) adaptive torque control that allows the user to always apply the same effort (torque) to the pedals, which is a very important function in case of sports activities dedicated to fitness recovery (e.g., for restorative activities after cardiac problems)

- (option, for wheel motors) adaptive control of charging (recovery) under braking or during normal activity by importing via smartphone different modes and extent of recovery. In case of mid-engine, it is possible to use any wheel motor connected to the control unit that will autonomously manage the adaptive recharge (see dedicated section at the bottom of the page)

- (standard) ability to select any type of battery and capacity setting that allows you to be able to monitor the actual energy available

- (standard) connection to the cloud for constant monitoring of system status through our server

- (standard) at least 20 user-callable performance settings including adaptive

- other features described in the manual

The smartphone-manageable control unit thus places no limits on the use of any type of battery, independently adjusting the parameters for optimal system operation. It will be possible to use 24 to 36V batteries of any type. It is also possible, from October 2022, to use 48V (14S) batteries with special care. It will suffice to indicate in the configuration the type of battery, rated voltage, capacity and maximum continuous current that can be delivered. The control unit will automatically determine the cutoff voltage to avoid BMS intervention. Lead-acid batteries are managed differently from other types because of the capacity that depends on the discharge current, so the available energy is managed in real time in a dedicated mode.

During the installation of our control unit, the bike is not modified as our control unit repurposes the same mounting points and dimensions and it is possible to use a smartphone attached to the handlebars to set its performance and obtain many parameters such as kilometers traveled, battery charge status (depending on the type), instantaneous current, residual energy, power, calories consumed and many other parameters (see main features or download or download the manual in the most updated version).

Power unit can be installed directly by the user or by our staff at our service laboratory (in which case the bike must be shipped or transported to our laboratory also using the agreed transport service with savings on expenses that are still included in the invoice). In case the user would like to install the control unit personally, he/she can do so by following the assembly guide video visible at this link. The warranty on ATEC Robotics components (Battery, control unit, torque sensor) is 2 or 5 years (if the purchase is made with extended warranty)

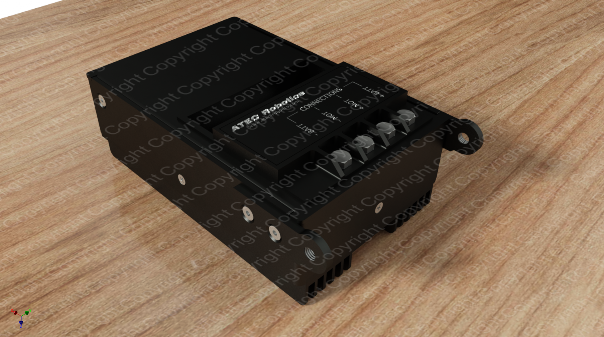

(Click on image to enlarge). The anodized aluminum radiator allows dissipation of heat produced by some electronic components. The temperature of the radiator is detected and reported in the operating data. If the expected temperature limit is exceeded, the control unit cuts off power to the engine. The attachment points of the control unit to the bike have been made perfectly compatible with the original ones. Mounting the control unit does not require any structural adaptation but it will be sufficient to screw the original screws back in. The new controller case in the next version 5 has the body totally made of aluminum made by laser cutting. Each one is numbered and a data base also shows the user's data.

(Click on image to enlarge). The connection of the control unit to the wiring harnesses is effected by means of a 25-pin connector allowing connection to all auxiliary devices, brakes, torque sensor, trottle (optional), wheel sensor, hall sensors, etc. The power section (battery and motor), on the other hand, is connected by means of 4 (brush) or 5 (brushless) dedicated connection points. Upon assembly, it will be sufficient to attach the supplied cables to the bike connectors, connect the battery and motor by means of the supplied cables. Then simply connect the 25-pin connector to the control unit and screw back the three fixing screws already on the bike. The new control unit in version 5 also has other attachment points for use on non-Aprilia bikes. The maximum power that can be managed in the basic version is 1kW.

Main Features

- Reproduces the shape of the original control unit and has the same mounting points for quick assembly even for non-experts (video assembly guide on the website)

- Fits all batteries (Lead, Lithium, LiFePo4, Ni-Cd, LiPo, LiMnO2 or other types) from 12V up to 60V.

- Thanks to the proprietary app on Android, it is possible to set all operating parameters of the control unit (maximum speed, maximum current, acceleration, deceleration, gain, release, etc.) and to read its values (also radiator temperature, torque signal, operating voltages, power, energy, current, etc.)

- GPRS tracker (optional) equipped with a built-in 3400mA battery. It recharges quickly once the controller is activated and remains active for about 25-40 days from the time the controller itself is turned off. It allows you to track the route and be alerted if the bike is touched by adjusting the sensitivity to avoid false alarms. The tracker can of course be deactivated by dedicated app.

- It is possible to set up to 20 types of modes of operation, that can be individually associated with the three levels of the selector, enabling the most frequently used or those desired for the specific route.

- Performance can be impulsive as in the case of the original control unit or with continuous assistance as in the case of PAS-equipped bikes.

- Allows you to set the cruise and 6km/h function for each configuration and customize it in terms of performance.

- Displays the values of the signal delivered by the torque sensor and has adaptive function for linearization of any sensor defects (due to aging and/or wear and tear)

- Automatically adjusts the base signal level of the torque sensor to compensate for performance differences between sensors and optimize performance.

- Visualization of brake lever signals to check their proper functionality

- Reuse of the original LED indicator: shows the remaining energy level 100%, 75%, 50%, 25%

- Energy bar at smartphone or tablet from 0 to 100% with 1% steps

- Energy computed according to energy level consumed or according to voltage level

- Energy recovery from motor if brushless or auxiliary generator/motor (front or rear wheel) independently managed by control system

- Adaptive function of the torque required from the user

- Audible indications at start-up or according to discharge limits reached

- Prepared for connection to gas throttle (gas throttle optional and on user responsibility)

- Measurement of speed and miles traveled via standard GPS or optional wheel sensor

- Send log file function in automatic mode or on user command to server for remote diagnostics

- Temperature sensor on radiator with temperature indication and power management according to temperature limits of power section

- Indication of battery voltage value and intermediate supply voltage (12Vn) for system monitoring and diagnostics

- Indication of instantaneous current drawn

- Radiator and control unit body in matte black anodized aluminum

- Android app for resetting/resetting the control unit in case of misconfigurations that affect its proper operation

- Calculation of calories consumed

- Other functions listed in the manual

- To discuss with one of our experts contact during office hours at +39.081.18918247 or 8/20h at +39.327.4016801

- To inquire about availability or book the control unit click here

Funzioni / Dispositivi Opzionali

- Generatore di corrente per la ricarica della batteria in discesa o durante il normale funzionamento in base alle impostazioni dell'utente ed in particolare:

Il generatore ausiliario o il motore sono utilizzati come generatore in fase di frenata, in discesa o durante il normale utilizzo. Naturalmente durante il normale fnzionamento se l'utente ha scelto la ricarica continua il motore funzionerà da generatore a livelli percentuali definiti dall''utente. Dopo un certo valore di coppia da parte dell'utente il sistema in autonomia passa dalla funzione generatore alla funzione motore. La soglia può essere adattiva o definita dall'utenmte semplicemente via app da smartphone.